Description

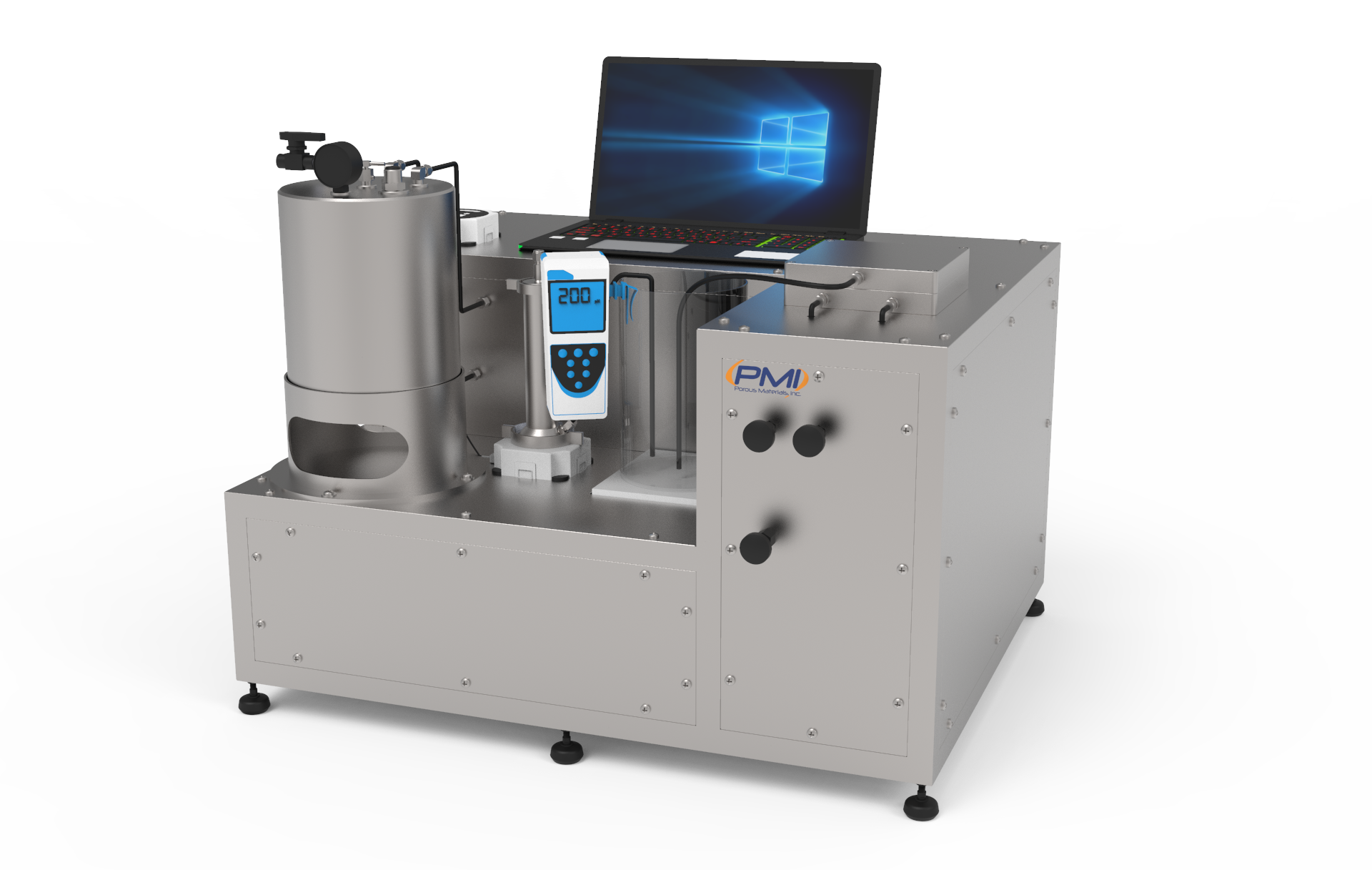

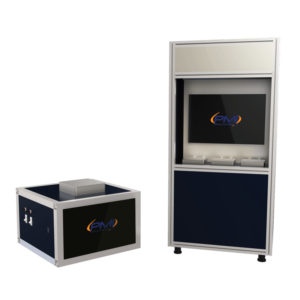

PMI’s Bench Scale Cross-flow and Dead-End Filtration System design for conducting MF/UF/NF/RO filtration experiment.

The Bench-scale cross-flow/Dead-end membrane experimental setup with recycle loop as design for membrane and filtration test. The cross-flow mode will be conducted in total recycle mode where the permeate will be collect permeate vessel and retentate will be recycled back into the feed tank. The membrane test cell has 100cm2 membrane effective filtration areas. The performance of the membrane process will assess and present as Flux versus Time, Salt rejection versus Time and Pressure with Time, Flow with Time. Membrane Flux decline and Salt rejection capability decline will be monitoring. The system performs cross-flow and dead-end tests from 0 to 500psi.

The dead-end mode the tank could pressurized up to 500 psi and magnetic starrier do mixing at stirred cell. The permeate will collect on permeate vessel. The conductivity, weight of permeate and pressure will be monitoring on software.

Features:

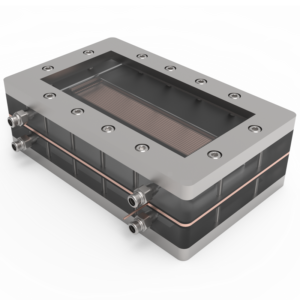

- Cross-flow filtration with flat sheet module (stainless steel)

- Dead-end filtration with stirred cell (stainless steel)

- Pressure control valve to adjust the pressure in the system

- Weight, Flow Rate, Pressure, Temperature, and conductivity monitoring

- Magnetic Stirrer Control Unit

- Pressure sensors

- pH and temperature control (optional)

Applications:

- Purification and concentration

- Membrane performance test

- Bio-fouling test

- Sample filtration from pilot or full-scale processes

- Fractionation, purification and concentration of molecules can be tested.