Rock Core instruments are fully automated. Execution, data storage and management are carried out effortlessly. PMI Rock Core instrument used for geological analysis, also used in industries like oil and mining. Core Flooding System, Core Saturators, Cylindrical Core Cutting Machine and more are some products manufactured by PMI.

Showing all 10 results

The CFS machine is useful for the oil and mining industry. Rock core samples are...

Read more

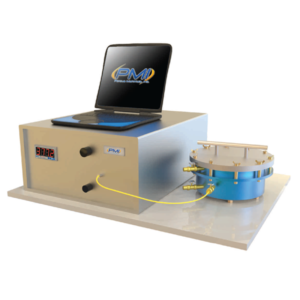

The PMI Pulse Decay Permeameter is designed to fully automatic measure the gas p...

Read more

The PMI Multi-Sample Porosimeter and Permeameter is a fully automatic instrument...

Read more

The PMl's CPS-2K is a computer-controlled system for the determination of capill...

Read more

The PMI Educational Gas Permeameter is designed for instructional use at univers...

Read more

The PMI Liquid Permeameter measures the steady state permeability of plug size...

Read more

PMI's Gas Pycnometer provides the user with a reliable measure of absolute densi...

Read more

The instrument is designed to accurate measure the effective porosity of plug si...

Read more

The PMI manual core saturator is designed to conduct a sequence of vacuum, satur...

Read more

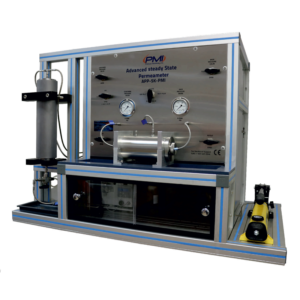

The PMI Steady State Liquid Permeameter is used to measure permeability of sampl...

Read more